Vintage Innovation: how to combine cutting-edge and old-school tech

In a fast-paced era of technological advancement exists a fertile ground of opportunity: vintage innovation.

When the word “vintage” is used, it often recalls images of retro fashion or classic cars. Contrary to popular belief, the principle of reviving, adapting, and fusing old inventions with new capabilities goes beyond aesthetic tastes and consumer goods. It may seem counterintuitive in a world racing for nanotechnology, quantum computing and artificial intelligence.

Yet, there is untapped potential to improve, explore or create new use-cases and current solutions, leveraging “commonplace” and “dormant” innovations. Companies often overlook residual tech innovations in larger projects, developed years ago, whose potential has not been fully explored. Employing a pragmatic approach to review vintage innovation opportunities can unearth this potential, solving other pain points or ameliorating current capacities.

“Vintage innovation refers to the strategic reinvigoration and application of underutilized or disregarded technologies, concepts, or processes, fused with modern advancements or adapted to new contexts, to create novel solutions, markets, or value propositions.”

It is therefore not an exercise in nostalgia but an attempt at reigniting a segment of strategy for business transformation that is too often overlooked.

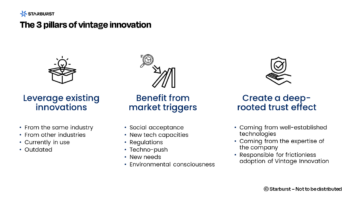

Vintage innovation exists if 3 conditions are satisfied

Symbolising a return to vintage innovation, wooden materials are making a strong comeback in modern construction. From new skyscrapers to parts of the Olympic Village in Paris, modernised and innovative forms of wood are more and more being used. This is partly due to innovations from other domains applied to wood, such as the chemical industry providing elaborate products (new adhesives, agglomerations, etc.) and the digital sector enabling simulation and complex structural calculation.

Yet, vintage innovation cannot only be defined by the improvement of technical properties by leveraging existing innovations (1). It also relies on a market trigger element (2) and a “deep-rooted trust” effect (3).

A process has been developed for creating wood concrete based on wood aggregates from sustainably managed forests. It offers a number of advantages over conventional concrete, including a lighter carbon footprint, greater lightness per cubic metre, easy cutting and better thermal and acoustic properties (1).

In addition to technical improvements from other industries, the wood industry has also benefited from an increase in demand for environmental-friendly construction, the greater availability of raw materials, and financial support for investment in the wood sector: these elements have been triggering demand (2). But essentially, wooden products benefit from a strong “deep-rooted trust” effect (3).

Wood has a worldwide reputation for robustness and durability in construction, a proven use over the years with historical wooden construction (church framing) and wood is culturally close to people, which makes new wood products easier to understand and adopt. Adoption was also driven by the company’s expertise in the field, relying on 15+ years of development in wood-related technologies.

Our research points out that there are 4 main types of vintage innovations

Categories of vintage innovation can be defined, according to the origin of the “dormant” innovation that is redeveloped and the impact of the newly created solutions. Such framework can help corporate better approach vintage innovation in their context.

Illustration of vintage innovation concepts

- Synergistic Fusion: Diphasic fire hose

Diphasic fire hoses are finally having an impact in modern firefighting techniques. Discussion and trials on diphasic systems have long been around but have never seen the day due to poor performance. The bottleneck was situated around the inability of misty streams of water to reach the source of the fire due to low exit speeds and extremely light water droplets. In 2022, startup Zelup has introduced a fire hose which expulses 1,5 billion droplets per litter of water by combining streams of pressurized air and water, at high exit speeds.

Historically, innovation in this field was centred around improving the volume of water being delivered to the fire source instead of focusing on the efficiency of the water delivered. The innovation here originates from the cleaning industry, where diphasic jets were used since 2012. Zelup in partnership with the Paris fire brigade managed to combine the technology behind the innovative cleaning appliance with high pressure nozzle systems for dispersion of water in fire hoses to birth a new product besting its predecessor in every way. Enhancements feature: particle collection in the air, up to 8 times less water consumption than classic fire hoses and enhanced thermal exchange offering optimal protection for the operator, while maintaining mobility.

In addition to technical improvements from other industries, the firefighting industry also benefited from an increase in the need for sustainable practices such as saving water, as well as the need to be able to fight new types of fires such as hydrocarbon-based fires, which the fire brigades were unable to effectively manage until now: demand for new solutions is not new. But essentially, a strong “deep-rooted trust” effect from the technology is essential, as life of firefighters and people relies on the fire hoses. The reliability of the process, the expertise of the company and the fact that the whole systems is based on water ensure that this innovation will be welcomed by public and private sector alike.

- Technology-Ahead-of-Its-Time: Solar panels

Solar cells have been existing since 1839 and Edmond Becquerel’s experimental demonstration of the photovoltaic effect. Many iterations occurred following the invention, but none were economically viable until photovoltaic technology was born in 1954. At the time, they could reach 4% efficiency. Today, thin-layer solar panels (the most common version of the technology), range from 15-22%. Still, at that time, these cells were too inefficient and expensive for mainstream applications. They found their use in the niche environment of satellites.

To become the cornerstone of renewable energy they are today, decades of technological advancements in modern engineering, materials science, and data analytics were required. Once confined to satellites and calculators, solar panels now grace rooftops of individuals, wearables, as well as smart grids to create more robust and sustainable energy ecosystems. Without improvement of side technologies, in particular to enable mass production, solar panels would not have found a new market.

- Cross-Industry Adaptation: AR/VR for industrial applications

Virtual Reality has been around since the 1960s, first conceived as a tool for immersive storytelling and simulation. For years, it remained in the domain of gaming and entertainment industries, with relative success.

In the early 1990s, David Mizell and Thomas Caudell developed the first industrial AR at Boeing. Using a head mounted display to superimpose a computer-generated diagram of the manufacturing process with a real-time world registration and the user’s head position calculation. The applications later evolved and offered significant improvements in assembly, maintenance and repair, training, quality control and commissioning, monitoring and visualization.

This technology is currently used by major corporations such as Renault, Airbus, L’Oreal, Toyota, Audi, Lockheed Martin, etc.

- Recontextualized Innovations: Michelin Inflatable Solutions

History

Michelin Inflatable Solutions was created in 2023 after the acquisition of AirCaptif, a startup that originated its activity in the manufacture of polyurethane kitesurfing bladders. Their first collaboration occurred in 2020 with the Michelin AIRPRONE inflatable medical cushions.

By leveraging core know-how on advanced materials and complex assemblies, Michelin Inflatable Solutions creates new solutions to answer demanding customer challenges. Mastering air and gas tightness enables robust, ultralight and ultracompact solutions. Enhancing those solutions with cutting-edge fabrics add functions to the solutions. In comparison to other alternatives, versatility and sustainability open new perspectives.

Among them, large inflatable Faraday cages for electromagnetic certification: Dassault Aviation’s Falcon 6X was fully tested and certified by EASA in a 900-square-meter modular Michelin Inflatable Solutions Faraday cage, in less than 2 weeks. This approach revolutionize the process, the test device is now coming to the plane, solving planning and costs issues.

Michelin Inflatable solutions, vintage innovation serving high value-added applications

Michelin has always been a very innovative company, with more than a thousand inventions that are now part of everyday life. For several years now, Michelin has started to deploy its expertise in composite materials in markets other than tires. For example: membranes for fuel-cells derived from coated polymers, high performance non-toxic resins derived from industrial applications, etc. Michelin Inflatable Solutions is a good example of industrial know-how combined with the agility and flexibility of a small business unit. Their way to innovate is also different: quick prototyping-testing loops rather than the usual long term innovation cycle.

An example of their competence is highlighted in the active cooling firefighting vest, developed in partnership with the Paris fire brigade, based on a patent from the BSPP (Brigade des Sapeurs Pompiers de Paris). The challenge was to find a durable solution to cool down firefighters – and avoid fainting due to high temperatures – without adding heavy weight nor reducing mobility.

Michelin drew on its expertise in inflatable solutions and advanced materials to develop two new technical layers to be added to firefighters’ outfits, providing both breathability and waterproof protection, with circulating air to dissipate the heat. Thanks to cutting-edge simulation tools, and quick feedback loops with the Paris fire Brigade, Michelin Inflatable Solutions was quickly able to launch an ultra-light prototype. The mastery of the technological building blocks and the ability to reuse and improve them has enabled Michelin to develop a fast and effective solution. A new solution that addresses a large worldwide market of firefighters who are all facing the same issues. Being part of the world-known group with a long-time expertise gives confidence in the ability to manage all the steps from product development to industrial production.

The 5 enablers of Michelin Inflatable Solutions’ success

- In-house technical know-how on main building blocks, leveraged with a strong collaboration with customers’ technical experts

- Among multiple opportunities, being able to focus on use cases with the biggest differentiation potential and the biggest chances of sucess

- Quick use case validation through early testing and customers’ involvement

- Quick prototyping abilities (expertise in simulation to decrease technical risks, speed of execution and result-oriented mindset)

- Continuous long-term innovation to develop new differentiating building blocks, based on customer unsatisfied needs

How can companies turn to the vintage innovation opportunity?

As illustrated by the Michelin initiative, vintage innovation is a component of the innovation strategy that should not be overlooked. 3 steps can be followed to set up an effective vintage innovation strategy.

- Qualify and assess the latest innovation products that have been developed over the last 3 years, by subdividing them into tech bricks

- Organise efficient capture of needs/innovations from other industries and from old in-house projects and prioritize them

- Analyze the shortlisted potential vintage innovation, qualify and prototype

A combination of those elements makes for an interesting source of value for industrial players

The world of business and technology is ever evolving, but it is crucial to remember that innovation doesn’t always come from reinventing the wheel. Vintage innovation underscores the value in reassessing dormant technologies, ideas, and capabilities that may have been sidelined due to their time’s constraints or lack of current relevance. By merging these “old” ideas with today’s technology, market trends, and needs, businesses can carve out new niches, diversify their portfolios, drive sustainable growth, and quickly and inexpensively put products on the market that solve high-value pain points for their clients. It’s a reminder for corporates worldwide: your next big breakthrough might just be hiding in an old R&D drawer.

Other perpectives:

- Read our memo on the rise in dual-use technologies.

- Discover our paper on how high-altitude balloons highlight the challenges and opportunities of the 20-50km range.

- Dive into aviation decarbonization options for short- and long-term solutions through different approaches through our article.